A

Algy

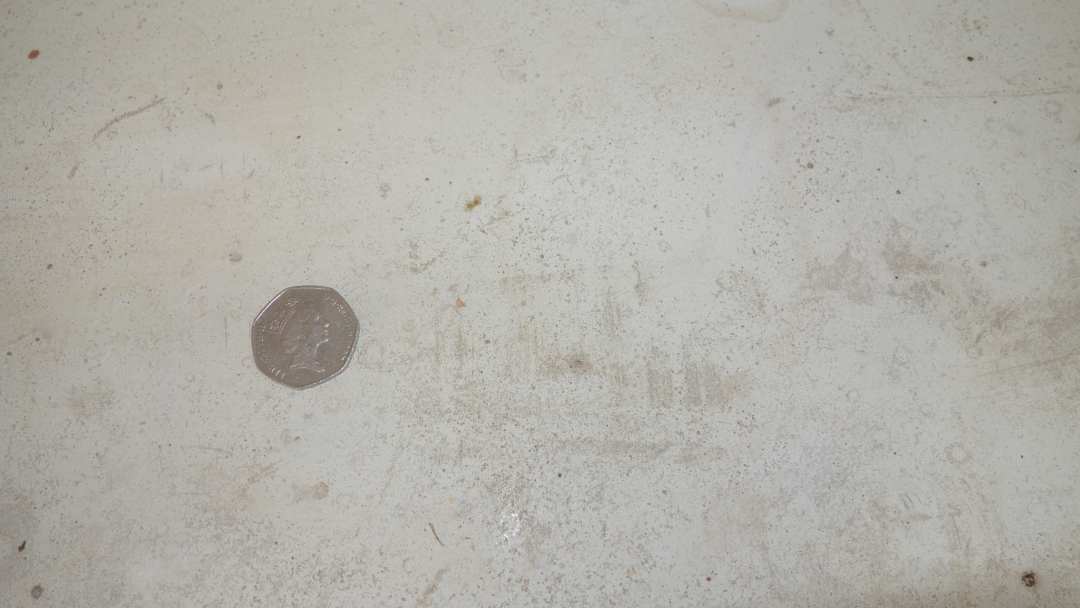

We had Lafarge gyvlon screed laid 4 years ago and are only now in a position to get it tiled. Up to now it was covered with temporary carpet.

As far as I can remember nothing has been done in prep (I know we should have removed the laitance a couple weeks after laying, but to be fair it looked sound and tiling was a long way in the future).

Now in looking at the surface it is still sound, surface clean, BUT very, very hard. Sanding it will be a challenge.

However, I want to do exactly what is right to have a lasting result. Nearly all forum advice seems to be to sand, but it is assuming that the screed is fairly freshly laid. What about 4 year old hard screed?

One professional advice was it had to be done and to be aware it would make an awful mess (we've now had a kitchen already fitted). A second professional says not needed now. So I am confused.

I've already decided to have a decoupling mat which every way we go, I really want to have a good result.

Desperate for advice please.

As far as I can remember nothing has been done in prep (I know we should have removed the laitance a couple weeks after laying, but to be fair it looked sound and tiling was a long way in the future).

Now in looking at the surface it is still sound, surface clean, BUT very, very hard. Sanding it will be a challenge.

However, I want to do exactly what is right to have a lasting result. Nearly all forum advice seems to be to sand, but it is assuming that the screed is fairly freshly laid. What about 4 year old hard screed?

One professional advice was it had to be done and to be aware it would make an awful mess (we've now had a kitchen already fitted). A second professional says not needed now. So I am confused.

I've already decided to have a decoupling mat which every way we go, I really want to have a good result.

Desperate for advice please.