We had some progress today, I was starting to wonder if Stone Masons took the entire month of January off!

We tried the tool today with various washer sizes and it was plainly obvious when we hit the right one, it just worked as we hoped.

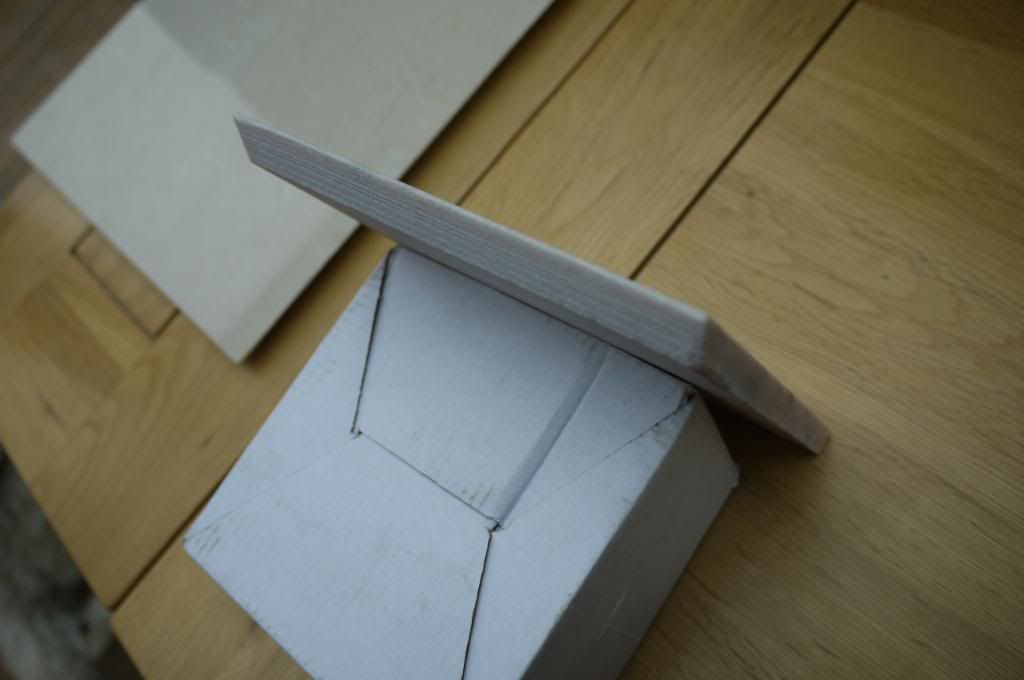

So today the mitre tool was run using a variable speed Matika grinder, dry, on 10mm thick marble, granite and Porcelain and a slightly thinner sample of Silestone quartz.

I brought the results home but it's too dark now to get decent close up images so I'll photograph over the weekend and you'll get an idea what finish this creates.

We learnt the following today.

Material determines the speed of cut rather than tool design.

These (materials) all cut dry, and as such we didn't bother with a wet test, on the grounds that if it works dry it will simply be faster and more controllable wet - so we don't need to test it.

This tool is not suitable for use on an angle grinder (circa 10,000 rpm) you simply can't control it. Particularly on porcelain, it "skips" during cutting. It will grind about 80% of the mitre fine, but once you get down to the detail the speed combined with the aggressive nature of the cutting head creates breakout and you end up with an untidy mitre.

The porcelain was by far the most difficult product for the tool to deal with, The marble and quartz it sailed through, at pretty much any speed dry.

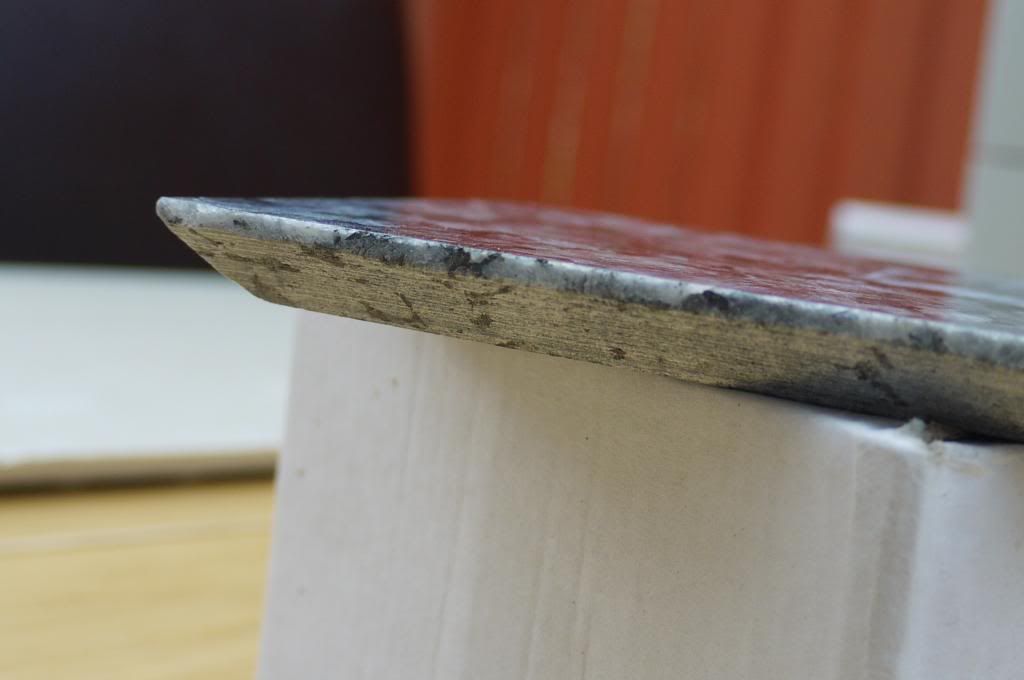

We tried a piece of granite, it happened to be Blue Pearl, with a coarse grained granite of that nature you needed to be slow to stop fracturing of the thin mitre edge.

Back to the porcelain, we didn't have any to hand to I popped down to the local CTD and bought a sample tile that was described as 10mm polished Porcelain suitable for walls and floors. This is Grade 4/5 and pretty dense. I figured it's unlikely you'll be mitring grade 5 flooring porcelain, it's more likely to be wall stuff but we needed to test this on some pretty dense product to see how it worked.

After a few runs it was obvious that we needed to be running speed 1 (the slowest) on the machine dry. Surprisingly this didn't slow the cutting down a great deal as the cutting head spent 100% of the time in contact with the tile surface rather than skipping about and ground it away evenly and neatly. I was timing what we were doing and I'd estimate it's going to take around 3 to 5 minutes to mitre a 300mm porcelain edge to a finish.

Surprise number 2 was the finish of the entire mitre was smooth, almost as if it had been finished with some emery paper and all smoothed off - not a sharp edge in sight. That wasn't something I'd even thought about.

We now need to run up a batch of the correct size washers, I'll get that done by a small precision engineering company in Norfolk next week at which point the first pieces will be available.

So I'm happy it works as intended but I'm a little disappointed it's not going to work on a grinder as that would open up the market tremendously.

I could modify the tool by using a less coarse grade of diamond allowing it run faster, that would create a few issues - heat and lifespan. So the compromise is it's got to be speed variable and unlikely that anything over 5,000 rpm is going to produce anything that would be considered acceptable results.

I'll add images over the weekend of cut edges so you get an idea what it can do.