Q

Qwerty

So I was recently asked to fit some 3m x 1.5m 6mm thin porcelain in a new tile showroom. Mapei & Sigma were present to supply tools, materials and their expertise with it.

Well we were naturally apprehensive at first as there were investors, the owner and reps galore present plus it was an all time first for us tilers. This was not a demo day or have a go day, these were full new sheets paid for by the owner, being fitted by me and a couple of others.

The first challenge was setting up the bed/ platform on which to set them down and cut them. This had been 'prepared' for us beforehand by the joiner on site but after an hours fettling by a couple of us and the @Mapei UK Marketing guys we had it as solid and as flat as we could possibly get it with what we had on site. Now in my opinion it wasn't as flat and as solid as it should have been and there was no cushioning on it at all.

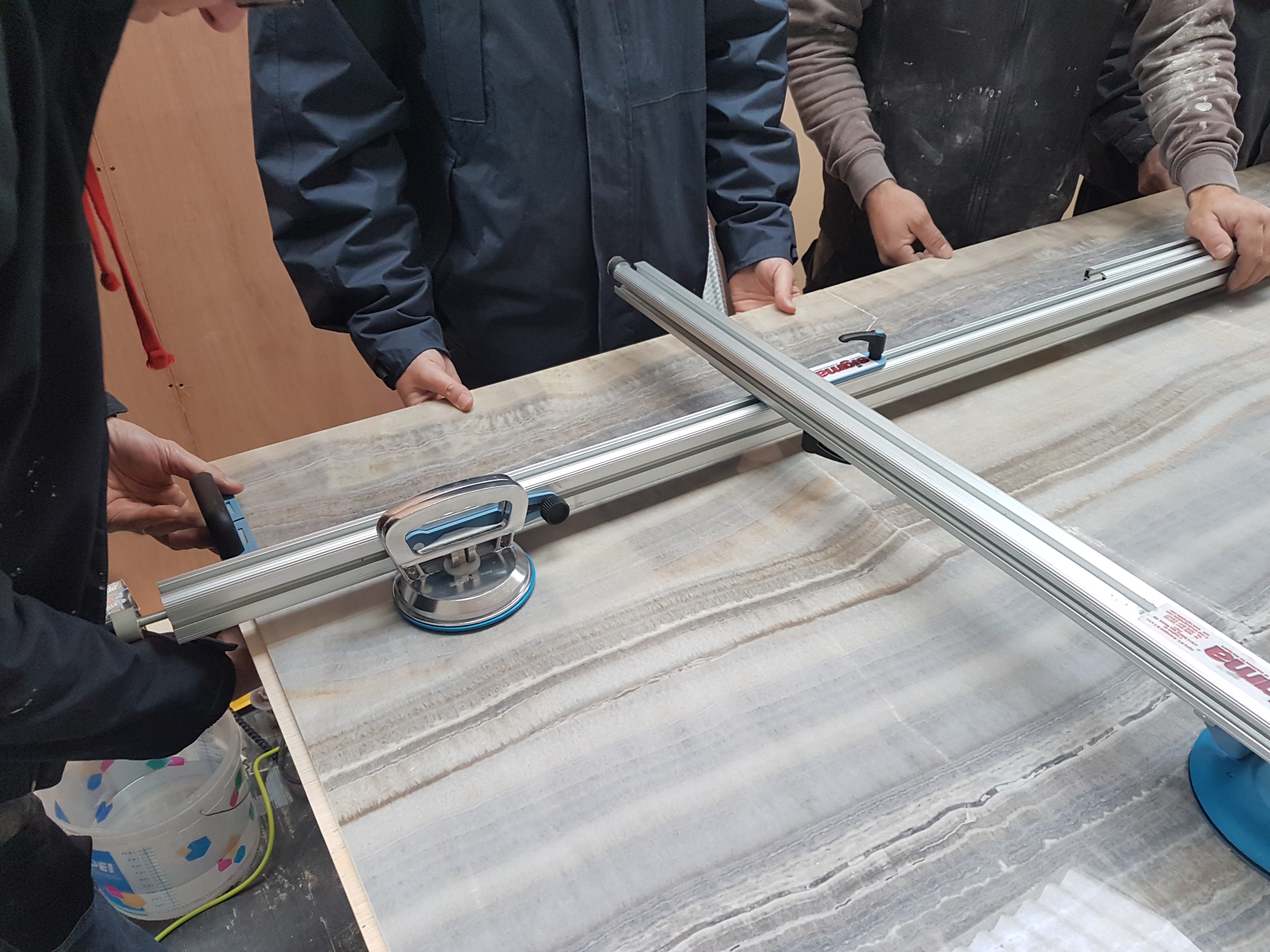

Derek from @Sigma UK had the keralift set up ready on top of the stack of slabs outside. The first piece was brought in and laid down safely. Now the area we were tiling was a straight forward 3 tile display which will ultimately be behind the counter (also tiled in a 6mm thin porcelain).

The first piece had to have a section at the top right corner cut out to accommodate the concrete roof truss and a hole drilled at the bottom for the till electric and data cables. 5mm was taken off the bottom also.

We carefully marked out and drilled two holes at the internal angles ready for the cuts. The long vertical cut was scored with the keracut and I then cut the two small cuts by hand with an angle grinder. It was then snapped at the end using the sigma breaker. The edges were then polished and then the 5mm was taken off the bottom and again polished.

It was then time to load the frame back on and offer it up.

Perfect fit! We were fortunate enough to have 6 guys to hand for the lifting and manoeuvring. Tools and static tiled display bays were the issue rather than the lifting but we had to work fast due to the suction of the cups potentially slowly releasing.

The wall was trowelled up with Mapei Ultralite and the back of the tile also. It was then lifted into position and gently bedded down into the adhesive.

Level sorted and then continue with tiles 2 & 3. Neither of these required cutting apart from tile 3 in the top left for more cables.

All in all it was a great learning experience. Mapei had some great advice regarding products for large format and they had a great level of knowledge about it all. Derek was spot on with the equipment and was also a font of knowledge!

A few days later a couple of us started on the counter in the same 6mm porcelain (but in a carrera marble effect). Again the joiner had made the counter. I personally would have liked to see it covered in backerboard but it was 18mm ply with a solid framework inside. We sorted out a few of the protruding screws and high spots and took a deep breath before starting!

The keracut and breaker was used to cut the tile almost in half length ways. It went well until cut sheared off and created an elliptical shaped break in the middle! All not lost as there was going to be a good 8cm wastage on one side of the tile anyway and the area where it was happened to be on the closing angle on top of the counter where it turns 45°. The pieces were cut to size again with a 10mm overlap on all sides to be mitred. Mitres were then cut freehand using the grinder.

Sadly I wasnt there to complete the final cuts as another local tiler I was with that day stayed on to finish it all off as I had to shoot on but all in all we were pretty happy with how it turned out.

Well we were naturally apprehensive at first as there were investors, the owner and reps galore present plus it was an all time first for us tilers. This was not a demo day or have a go day, these were full new sheets paid for by the owner, being fitted by me and a couple of others.

The first challenge was setting up the bed/ platform on which to set them down and cut them. This had been 'prepared' for us beforehand by the joiner on site but after an hours fettling by a couple of us and the @Mapei UK Marketing guys we had it as solid and as flat as we could possibly get it with what we had on site. Now in my opinion it wasn't as flat and as solid as it should have been and there was no cushioning on it at all.

Derek from @Sigma UK had the keralift set up ready on top of the stack of slabs outside. The first piece was brought in and laid down safely. Now the area we were tiling was a straight forward 3 tile display which will ultimately be behind the counter (also tiled in a 6mm thin porcelain).

The first piece had to have a section at the top right corner cut out to accommodate the concrete roof truss and a hole drilled at the bottom for the till electric and data cables. 5mm was taken off the bottom also.

We carefully marked out and drilled two holes at the internal angles ready for the cuts. The long vertical cut was scored with the keracut and I then cut the two small cuts by hand with an angle grinder. It was then snapped at the end using the sigma breaker. The edges were then polished and then the 5mm was taken off the bottom and again polished.

It was then time to load the frame back on and offer it up.

Perfect fit! We were fortunate enough to have 6 guys to hand for the lifting and manoeuvring. Tools and static tiled display bays were the issue rather than the lifting but we had to work fast due to the suction of the cups potentially slowly releasing.

The wall was trowelled up with Mapei Ultralite and the back of the tile also. It was then lifted into position and gently bedded down into the adhesive.

Level sorted and then continue with tiles 2 & 3. Neither of these required cutting apart from tile 3 in the top left for more cables.

All in all it was a great learning experience. Mapei had some great advice regarding products for large format and they had a great level of knowledge about it all. Derek was spot on with the equipment and was also a font of knowledge!

A few days later a couple of us started on the counter in the same 6mm porcelain (but in a carrera marble effect). Again the joiner had made the counter. I personally would have liked to see it covered in backerboard but it was 18mm ply with a solid framework inside. We sorted out a few of the protruding screws and high spots and took a deep breath before starting!

The keracut and breaker was used to cut the tile almost in half length ways. It went well until cut sheared off and created an elliptical shaped break in the middle! All not lost as there was going to be a good 8cm wastage on one side of the tile anyway and the area where it was happened to be on the closing angle on top of the counter where it turns 45°. The pieces were cut to size again with a 10mm overlap on all sides to be mitred. Mitres were then cut freehand using the grinder.

Sadly I wasnt there to complete the final cuts as another local tiler I was with that day stayed on to finish it all off as I had to shoot on but all in all we were pretty happy with how it turned out.