M

mp3wizard

Hi All,

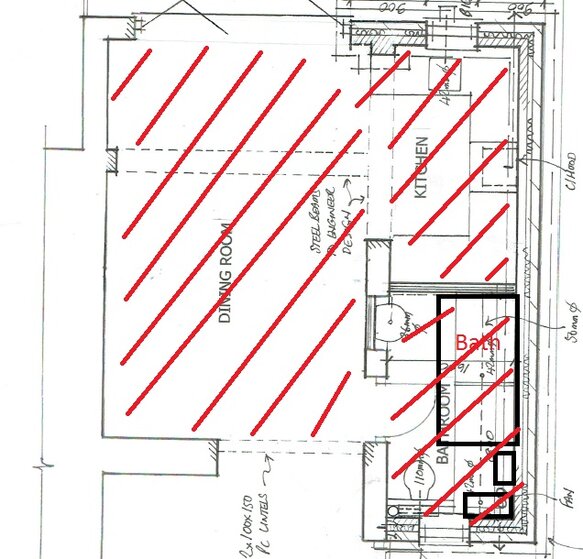

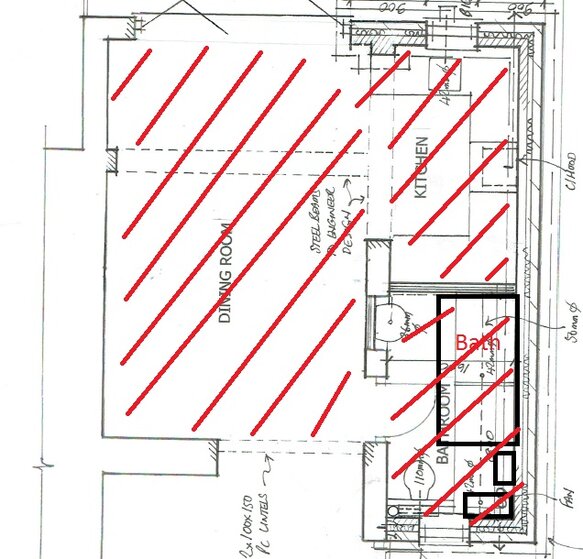

I've just had an extension done and I'm wondering how best to tile the room, I am a novice and haven't tiled before, as if that wasn't hard enough, I am also fitting underfloor heating and dealing with 800mm by 800mm floor tiles.

From the attached picture I am looking to tile the red lined areas, I haven’t got any kitchen or bathroom fitted so the floor is completely free for tiling, the only obstacle in my way is the soil pipe in bathroom and a few radiator pipes, I was intending to mark the size of soil pipe on the tile and use an angle grinder to cut the shape out on the tile, would you agree this is the best method? And for the radiators to cut out a square piece and cut the remainder of the small piece of tile to put behind the pipe and use a filler for any gaps?

From the research I have done, a lot of people advise to start from the centre of the room, but because the living room, kitchen, bathroom will all be the same tile and I want it to flow and I wonder if starting from the centre of the living room is really the best idea?

I have been told that it would be a good ideal to use a levelling compound or levelling boards, for the underfloor heating, but It’s a new wood floor fitted with big wooden sheets, which is quite level and underneath that is 100mm in insulation boards, so my plan was to coat the floor in some heatflex which is a primer used to stop heat escape for underfloor heating, then the underfloor heating mats, and then the mapei adhesive recommended for the tile, then the tile and grout as normal.

The tools I’ve got for the job are;

Electric Wet cutter, dry cutter (800mm wide), mixing trowel, 6mm notched trowel, plastic scraper for grout, grout float, 2 mixing buckets, sprit level, 3mm tile spacers, suction grabber, 4 hard sponges, heatflex primer, adhesvies and grout, tape measure, square edge.

I’d appreciate any input as I’d like a good finish and if there are any additional tools that you think I might need.

Thanks a lot.

Mark

I've just had an extension done and I'm wondering how best to tile the room, I am a novice and haven't tiled before, as if that wasn't hard enough, I am also fitting underfloor heating and dealing with 800mm by 800mm floor tiles.

From the attached picture I am looking to tile the red lined areas, I haven’t got any kitchen or bathroom fitted so the floor is completely free for tiling, the only obstacle in my way is the soil pipe in bathroom and a few radiator pipes, I was intending to mark the size of soil pipe on the tile and use an angle grinder to cut the shape out on the tile, would you agree this is the best method? And for the radiators to cut out a square piece and cut the remainder of the small piece of tile to put behind the pipe and use a filler for any gaps?

From the research I have done, a lot of people advise to start from the centre of the room, but because the living room, kitchen, bathroom will all be the same tile and I want it to flow and I wonder if starting from the centre of the living room is really the best idea?

I have been told that it would be a good ideal to use a levelling compound or levelling boards, for the underfloor heating, but It’s a new wood floor fitted with big wooden sheets, which is quite level and underneath that is 100mm in insulation boards, so my plan was to coat the floor in some heatflex which is a primer used to stop heat escape for underfloor heating, then the underfloor heating mats, and then the mapei adhesive recommended for the tile, then the tile and grout as normal.

The tools I’ve got for the job are;

Electric Wet cutter, dry cutter (800mm wide), mixing trowel, 6mm notched trowel, plastic scraper for grout, grout float, 2 mixing buckets, sprit level, 3mm tile spacers, suction grabber, 4 hard sponges, heatflex primer, adhesvies and grout, tape measure, square edge.

I’d appreciate any input as I’d like a good finish and if there are any additional tools that you think I might need.

Thanks a lot.

Mark