Hi everyone,

I am looking for some technical advice on reusing Wedi board in a shower floor. Below is some background information.

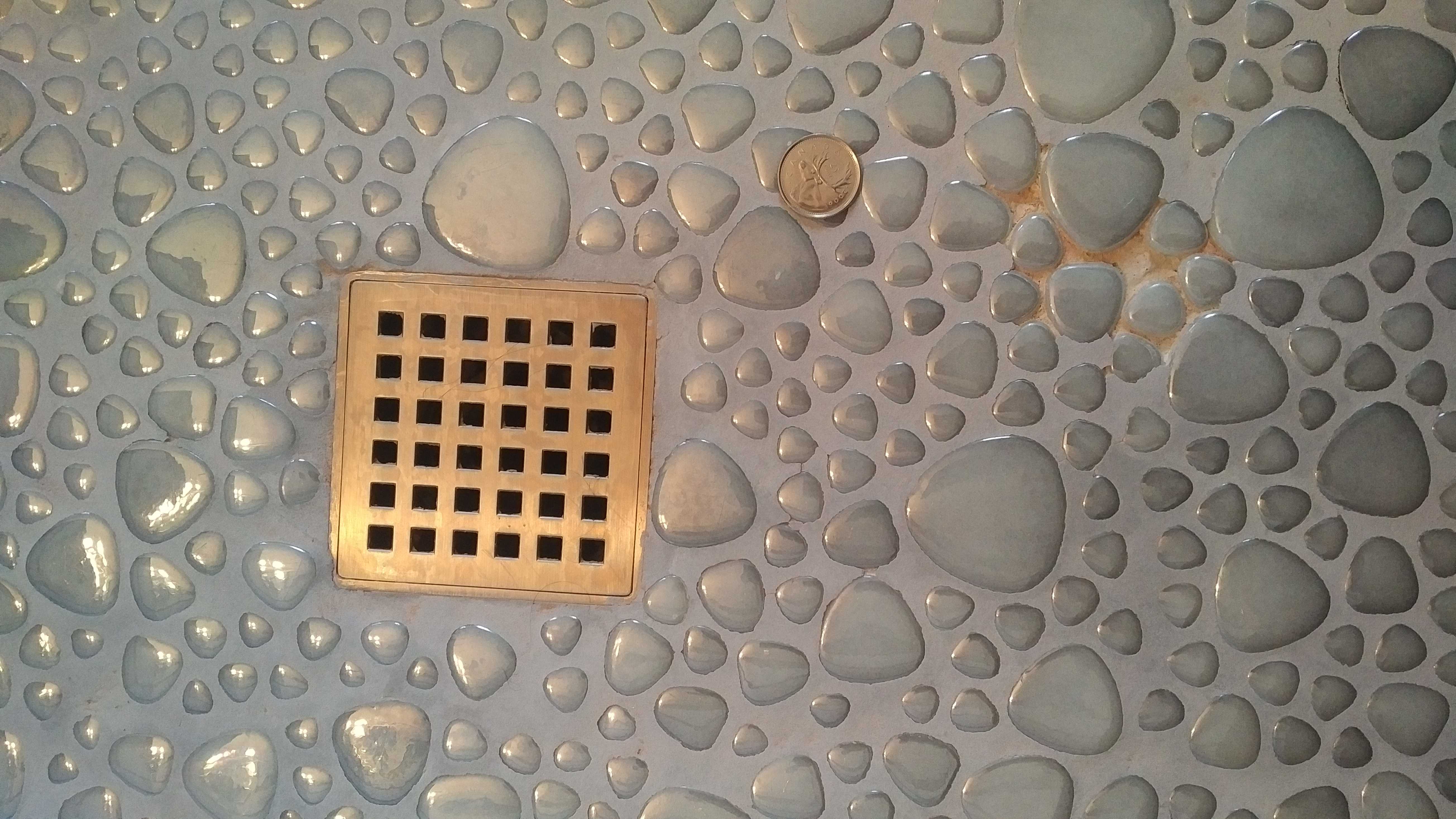

I have a Wedi Certified contractor who renovated my bathroom which included installing a Wedi shower. The work was completed in December 2017 and there have been issues with the tiled floor from the beginning. It is roughly a 60"x30" floor installed with glass pebble mosaic tiles and silver Kiesel unsanded grout. The 1st photo shows the current floor. The current issue is that the grout is coming out (see the 2nd photo). The problem would seem to be the type of grout used as the gaps between tiles are well over 1/8" which is not meant for unsanded grout. The contractor wants to remove the grout, tile and mortar and reinstall it all but use epoxy grout instead. The concern I have with this plan is the Wedi system could be damaged. On the Wedi website, it indicates not to use tools like hammers to remove the tile as the impact and vibration could compromise the integrity of the waterproofing. If the impact and vibration can be avoided, I am still concerned that the outer layer of the Wedi board, which provides strength to the Wedi board and gives the tile mortar a good surface to bond to, could be damaged which I can't imagine would be good for a floor installation. I suggested instead that only the grout be removed and replaced to avoid damaging the Wedi board. The contractor's concern with this is the possibility of not getting all of the grout removed.

What recommendations can you offer to fix this problem?

For your information, below are the other issues I have had:

- Shortly after the shower was installed I noticed there was one spot that took hours to dry. On closer inspection I discovered there was some cracked grout around a few tiles (see the 3rd photo). During that closer inspection, I found that there where pinholes throughout all of the shower floor grout (this can also be seen in the 3rd photo). I also found a few spots where there were white globs of either other grout or mortar on the tile and floor grout (see the 4th photo). In general the grout application did not look smooth/even. The contractor came and fixed the cracked grout and removed the white globs but there were still white areas within the silver grout. Nothing was done about the pinholes or uneveness.

- After the first fix, as time went on, I noticed that the shower floor seemed to take longer and longer to dry with some areas taking hours. Eventually the grout started turning orange and smelled moldy. On closer inspection it looked like the pinholes had got larger and there were a few small gaps between grout and tile (see the 5th and 6th photos). The contractor came back and fixed things - I am not sure how it was done, but at the end the surface was quite even/smooth with the pinholes and white spots in the grout gone. One odd thing is that the 2 left corners stayed dark for a few days after (even after showers) but eventually lightened to match the rest of the floor though it left a few brown marks (see 7th photo).

- Some time after that I then noticed that there was a continuous crack along most of the left side close to the edge with some cracking around one of the tiles (see the 8th, 9th and 10th photos). After that it then seemed that sometimes, mostly on the left side, there were areas which would take hours to try. The most recent issue is the grout coming out as mentioned at the beginning of this post. This started on the left side near the drain but now looks to be starting on the right side near the drain and you can see other areas where it will likely start to fail.

As a general note, the contractor's employees are typically jack-of-all-trades types and I don't know if any of them have had any formal tile training and in my opinion, the tiling work done is average at best. Lots of lippage and they don't have great attention to detail. The owner is definitely the most skilled but he typically doesn't do much of the work. He did do the second fix (which looked way better than the original installation) and he plans to do the current fix. I also suggested that he arrange for someone with more expertise do the current fix, but he said I would have to go through insurance for that.

I should also mention that I did mention my concerns to him about using unsanded grout before the shower was installed but he preferred to use it over sanded grout which would scratch the tiles.

Any feedback you can provide would be greatly appreciated.

Thanks!

I am looking for some technical advice on reusing Wedi board in a shower floor. Below is some background information.

I have a Wedi Certified contractor who renovated my bathroom which included installing a Wedi shower. The work was completed in December 2017 and there have been issues with the tiled floor from the beginning. It is roughly a 60"x30" floor installed with glass pebble mosaic tiles and silver Kiesel unsanded grout. The 1st photo shows the current floor. The current issue is that the grout is coming out (see the 2nd photo). The problem would seem to be the type of grout used as the gaps between tiles are well over 1/8" which is not meant for unsanded grout. The contractor wants to remove the grout, tile and mortar and reinstall it all but use epoxy grout instead. The concern I have with this plan is the Wedi system could be damaged. On the Wedi website, it indicates not to use tools like hammers to remove the tile as the impact and vibration could compromise the integrity of the waterproofing. If the impact and vibration can be avoided, I am still concerned that the outer layer of the Wedi board, which provides strength to the Wedi board and gives the tile mortar a good surface to bond to, could be damaged which I can't imagine would be good for a floor installation. I suggested instead that only the grout be removed and replaced to avoid damaging the Wedi board. The contractor's concern with this is the possibility of not getting all of the grout removed.

What recommendations can you offer to fix this problem?

For your information, below are the other issues I have had:

- Shortly after the shower was installed I noticed there was one spot that took hours to dry. On closer inspection I discovered there was some cracked grout around a few tiles (see the 3rd photo). During that closer inspection, I found that there where pinholes throughout all of the shower floor grout (this can also be seen in the 3rd photo). I also found a few spots where there were white globs of either other grout or mortar on the tile and floor grout (see the 4th photo). In general the grout application did not look smooth/even. The contractor came and fixed the cracked grout and removed the white globs but there were still white areas within the silver grout. Nothing was done about the pinholes or uneveness.

- After the first fix, as time went on, I noticed that the shower floor seemed to take longer and longer to dry with some areas taking hours. Eventually the grout started turning orange and smelled moldy. On closer inspection it looked like the pinholes had got larger and there were a few small gaps between grout and tile (see the 5th and 6th photos). The contractor came back and fixed things - I am not sure how it was done, but at the end the surface was quite even/smooth with the pinholes and white spots in the grout gone. One odd thing is that the 2 left corners stayed dark for a few days after (even after showers) but eventually lightened to match the rest of the floor though it left a few brown marks (see 7th photo).

- Some time after that I then noticed that there was a continuous crack along most of the left side close to the edge with some cracking around one of the tiles (see the 8th, 9th and 10th photos). After that it then seemed that sometimes, mostly on the left side, there were areas which would take hours to try. The most recent issue is the grout coming out as mentioned at the beginning of this post. This started on the left side near the drain but now looks to be starting on the right side near the drain and you can see other areas where it will likely start to fail.

As a general note, the contractor's employees are typically jack-of-all-trades types and I don't know if any of them have had any formal tile training and in my opinion, the tiling work done is average at best. Lots of lippage and they don't have great attention to detail. The owner is definitely the most skilled but he typically doesn't do much of the work. He did do the second fix (which looked way better than the original installation) and he plans to do the current fix. I also suggested that he arrange for someone with more expertise do the current fix, but he said I would have to go through insurance for that.

I should also mention that I did mention my concerns to him about using unsanded grout before the shower was installed but he preferred to use it over sanded grout which would scratch the tiles.

Any feedback you can provide would be greatly appreciated.

Thanks!