F

Fourcircles

Hello again! Quick question:

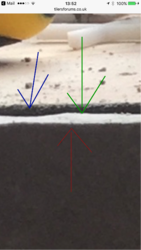

What is the best way to get accurate, level cuts on all tiles around the window frame so that the trim sits flush?

I am at this point now - all my cuts so far have been with a wet saw and have turned out ok, but my understanding with trim is that you have very little room for error. It doesn't help either that my reveals aren't completely level.

My tiles are 600x300 so I can't use the wet saw guide.

Thanks in advance

What is the best way to get accurate, level cuts on all tiles around the window frame so that the trim sits flush?

I am at this point now - all my cuts so far have been with a wet saw and have turned out ok, but my understanding with trim is that you have very little room for error. It doesn't help either that my reveals aren't completely level.

My tiles are 600x300 so I can't use the wet saw guide.

Thanks in advance