D

Deleted member 51481

Hello All,

After a few months respite I'm back. Some of you may recall my pre-Christmas dilemma with laying 30+sqm porcelain on what I thought was a unlevel slab. Well I heeded everyone's advice and got a professional tiler in who did a superb job and it turned out the floor was only 5mm lower in one section so saved myself a few quid by not having to get the screeders in. I (my tiler) even managed to get the thresholds bang on so am a very happy customer.

Fast forward five months and now I'm going external with the same tiles but 20mm instead of 10mm.

The coffers are dry so am planning to do everything myself this time round as the weather is good, no tight deadlines like before and is its external it doesn't have to be 100% perfect.

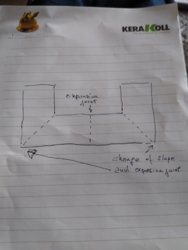

I've read and been advised by my tiler that the recommended method is to lay porcelain on a concrete slab which I'm preparing currently - which is 40 sqm - sqm on the front of a building and 20 sqm on the left so there is a right angle corner.

I've created a fall on the shuttering by using a long spirit level and made sure the bubble sits proud on the little line in the bubble window – sorry but I am a lay man – I hope this is enough fall!

My question is am I doing this right because what I’m worried about is when I pour the concrete it will sink to the lowest point.

Also due to access issues am I going to mix the concrete with an oversized mixer and wheel barrow it into place. In my simple mind I will do it in sections too, am I mad to do it this like this?

Attached are pics.

Thanks.

After a few months respite I'm back. Some of you may recall my pre-Christmas dilemma with laying 30+sqm porcelain on what I thought was a unlevel slab. Well I heeded everyone's advice and got a professional tiler in who did a superb job and it turned out the floor was only 5mm lower in one section so saved myself a few quid by not having to get the screeders in. I (my tiler) even managed to get the thresholds bang on so am a very happy customer.

Fast forward five months and now I'm going external with the same tiles but 20mm instead of 10mm.

The coffers are dry so am planning to do everything myself this time round as the weather is good, no tight deadlines like before and is its external it doesn't have to be 100% perfect.

I've read and been advised by my tiler that the recommended method is to lay porcelain on a concrete slab which I'm preparing currently - which is 40 sqm - sqm on the front of a building and 20 sqm on the left so there is a right angle corner.

I've created a fall on the shuttering by using a long spirit level and made sure the bubble sits proud on the little line in the bubble window – sorry but I am a lay man – I hope this is enough fall!

My question is am I doing this right because what I’m worried about is when I pour the concrete it will sink to the lowest point.

Also due to access issues am I going to mix the concrete with an oversized mixer and wheel barrow it into place. In my simple mind I will do it in sections too, am I mad to do it this like this?

Attached are pics.

Thanks.