P

philrab66

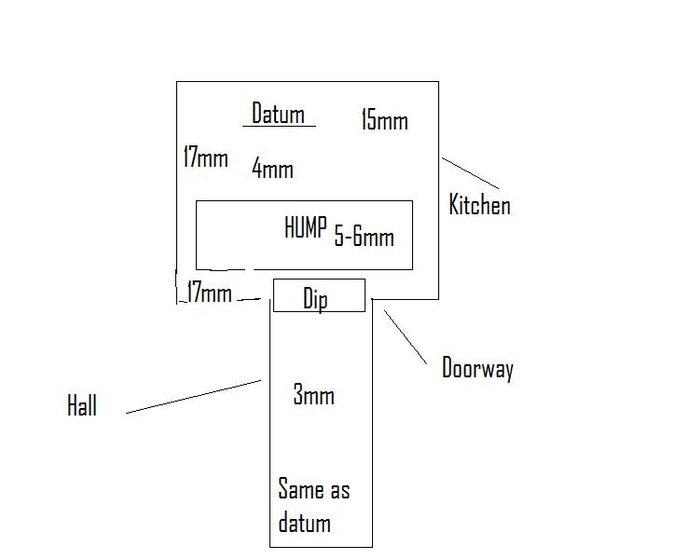

Thanks for that Freefall. Only trouble is I already have a layer down. I went round with a level today like thisMaybe an easier way for u then is to lay a thin runner that is level to the area u want to match and u can pour your latex and pull a straight edge over your runners to achieve a level surface. That might not make sense at first but here's an image of the technique. I use it myself sometimes if it's particularly complicated. Just remember to not pull too quickly because it'll drag the latex back out.

View attachment 73559 View attachment 73560 View attachment 73561

So set your runners level, packing them where necessary. Support them well because when u use a straight edge on them they will bend if u apply too much pressure

Pour in your latex and pull a metal straight edge back over the runners to achieve a level surface. Remove the runners after and fill in. It's fussy and time consuming but the end result is a perfectly flat and level floor. Which will halve your fixing time and save u a fortune in adhesive.

I have uploaded a crude picture.