A

alexander

Hi Tilers forum,

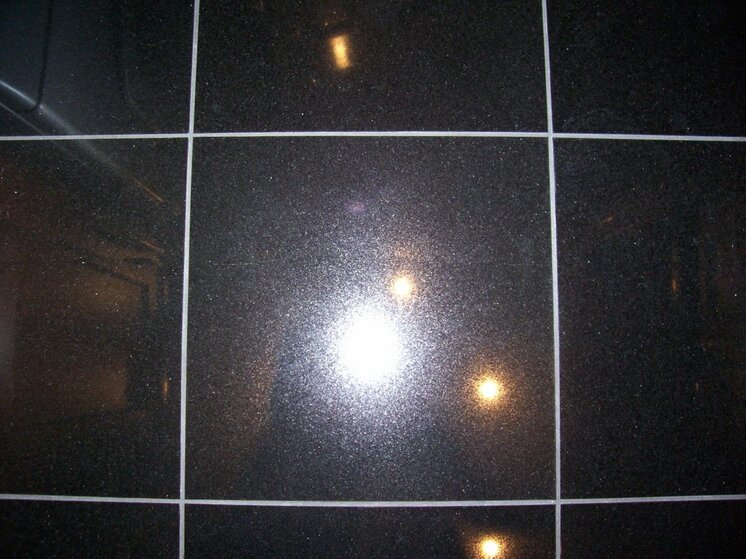

These pics are of a conglomerate granite bathroom floor 5m2 about 4 months old.

Customer recently noticed fault lines appearing across the tiles in three places.

The fault lines(beginning of cracks) run across 3 or more tiles but seem to unaffect the grout and tiles still seem well bonded.

At the same time the bathroom was done the adjacent kitchen floor was tiled in 600x600 porc 20m2, the kitchen floor remains ok at this time.

The prep and materials for each floor was the same. 9mm no more ply was glued and fixed to the timber floor boards and tiled using single part flex addy and grout.

Thanks for looking, regards craig new member.