I don't know how many guys on this forum know Karl dahm but they are consistently the best in the business for tools and cutters .some of their own cutters look so basic but they do the job..

just want to say something about karl dahm. i not very often buy my tools at karl dahm. he has a good catalouge and sortiment but all is expensive. something of his inventions seems a little bit to strange for me.

@houston

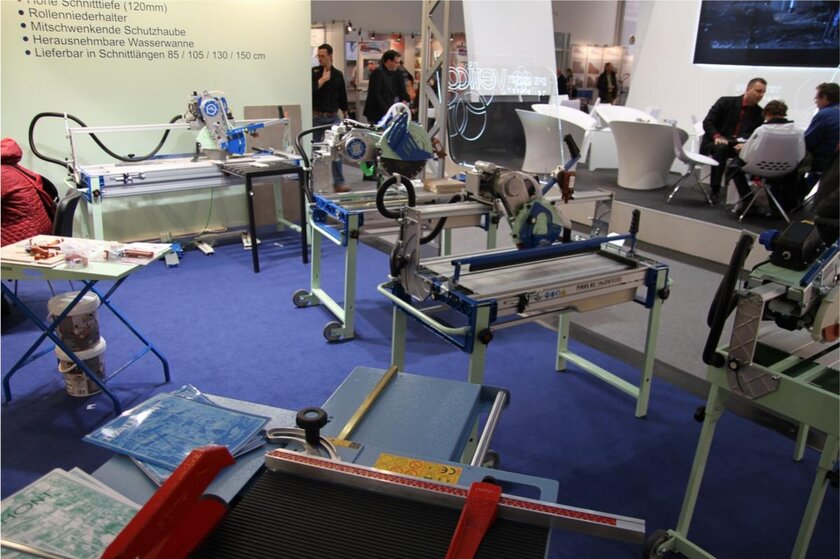

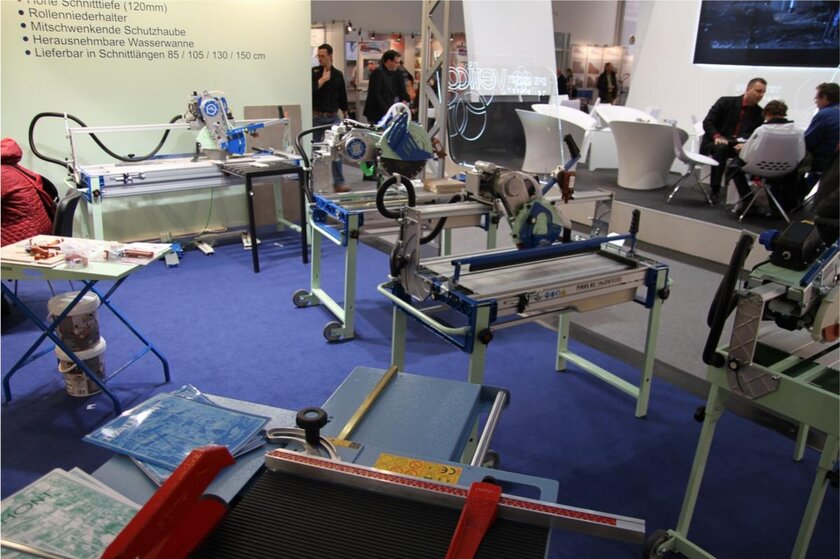

i was this week on the BAU fair in munich and can talk a little bit about wet saws here:

the wet saws called karl dahm supercut are from

Englhard Maschinenbau . so the advantage of contacting the producer direktly is he can make special versions or special lengths and so on. he also build the highline wooden dry cutters for karl dahm. i saw his new machine on the BAU Fairand talked to him what he´s planing. he goes not in my direktion but maby he has interesting produkts for someone else in the pipeline. a dry cutter for 3m tiles based on a solid table. the table is also available without the rail. its just a solid table.

then a new light 1,80m wet waw for wet and dry cutting. with an light engine and the option to change the diamond blade with an dry unit. so you can use your wet saw for cutting tiles like on a tile cutter. a special breakage unit is also on board. the machine can also completle fragmented.

for me it is no praktical thing. if i have a site i use big tiles, i need the dry tile cutter and the wet saw. and i never take my wet saw to a site when i just need a dry tile cutter. and i don´t want to convert it with screws on site more often.

i use myself a englhard "meistergold fahrbar" and this is a very solid but also heavy machine. the rail profile is perfekt for wet saws. as you see on the photos i use the 2,50m rail for my custom saw and it is with no flex or something. the machine has a little bit problems about handling. i don´t like the position of the grip and the water sprays alwas on you when you. but quality is realy good for the price. miters can be do by array the table. for fast work with normal formats i like this more. good machine build by an mechanical engeneer not by a tiler.

the kaufmann saws from austria (

Kaufmann Göfis ) have a good feature i like very lot. the fence for tiles or stone is not in front and can disguised because of transport or something or flex from 90tie to someting else because of the tiles length. you can clip two ones on the side of the watertub or on the side tables. the machines has a feeling like wooden saws. i think thin stripes can be cut very accurate without flexing the fence. for miters you can fix the tile also better with the side fences. this is a good feature i like. maby i buy a titan saw in 2.50cm length it depends of a few trials this year. i think its a very longlive machine. every part of the machine can be ordered.

here ar pics from italmont (

Italmont Home ). they distribute the raimondi machines (

:: Raimondi Utensili - Home Page :: ). i can´t tell you about this machines but the raimondi produkts i have in use (core drilling machine) are very practical.

i tried the sigma rail cutter. thats a very simple tool. i like it from the feeling more than the raimondi free cut and the suction caps are not really needed. the disadvantage of the sigma is he can not separable. but i like the handling, the massive rail and the easy running slide.

anyone here has got such a mix machine? i think i want to buy one for the shower screeds i have to made or to equal stairs. thats a very light small and simple machine. the engine is saved on bottom and the mix linkage is very massive and easy to clean.

another thing i wanted to buy is a dust killer. something like that:

http://www.werkzeuge-mit-ideen.de/admin/show_image.php?id=17967&height=400&width=400

anyone experience with equipment like this?

the one on the photo is a dry machine with high power. it cleans until 3400 m³/h . my idea was to use this one not only on bathroom renovations ore other renovations . i wanted to use it on site to fix the pipe on the table i grind dry with angle grinder. i produce a lot of dust and i think this machine reduce it very good. but the price is huge!! 2500euro is a really big invest for something i don´t know it it works well.

ah by the way i can´t resist temptation. i want to test it tomorrow.

there are a few points i want to improve it. and if it works well i got the idea of a new selfmade machine. maby i build up a prototype next week.