R

rainsco

hallo,

in my winter holidays i thinked a lot about tony.

i do mitres in most of my jobs.

i have two wet saws in diffrent lengths and weights and i use the light one almost every day because i can drag it out of my car in seconds and use it outdoor or indoor in my self built wet box.

but last year i had two jobs where i can´t use my wet saws. 5th floor and no place for it or the tiles were to long and heavy to handle on the mobile saws.

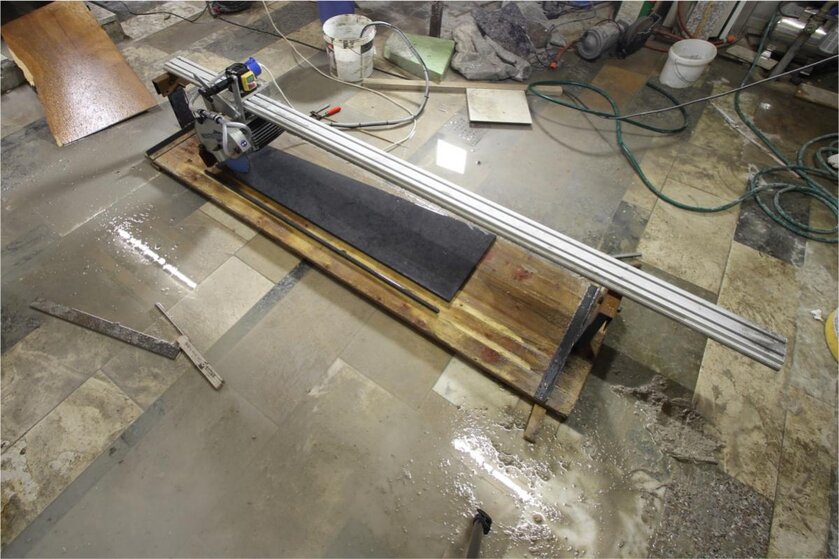

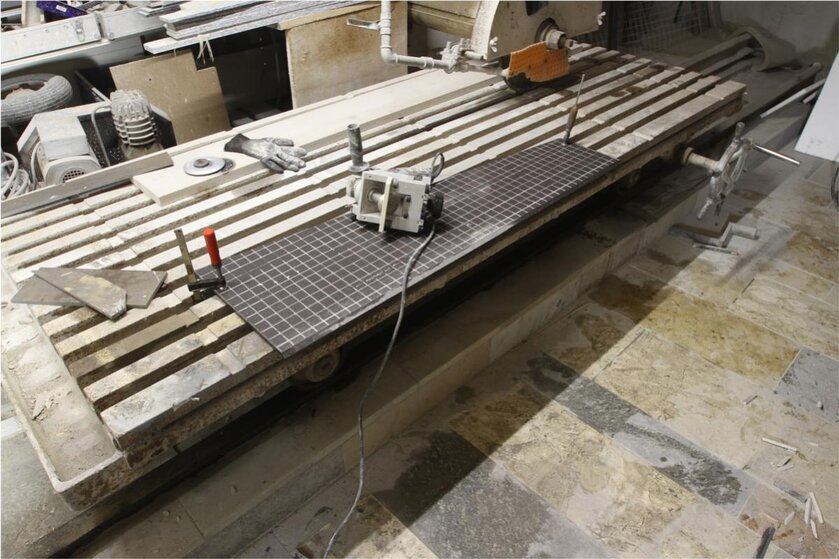

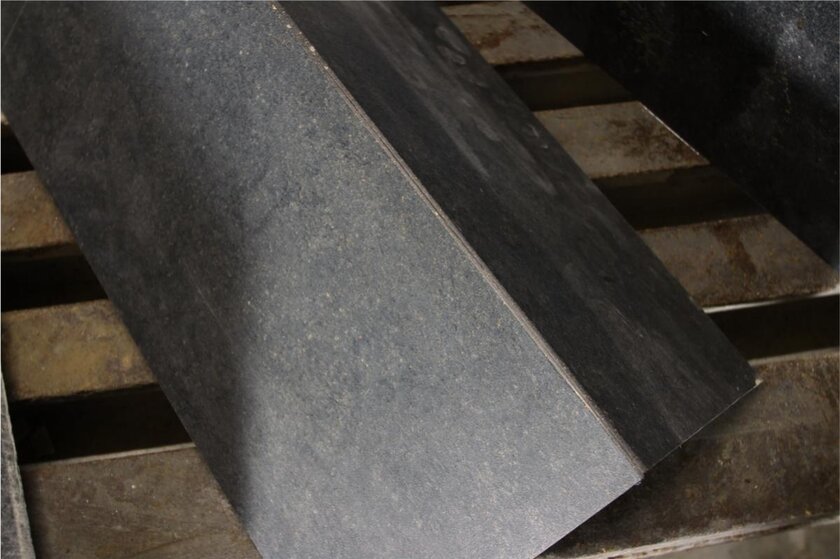

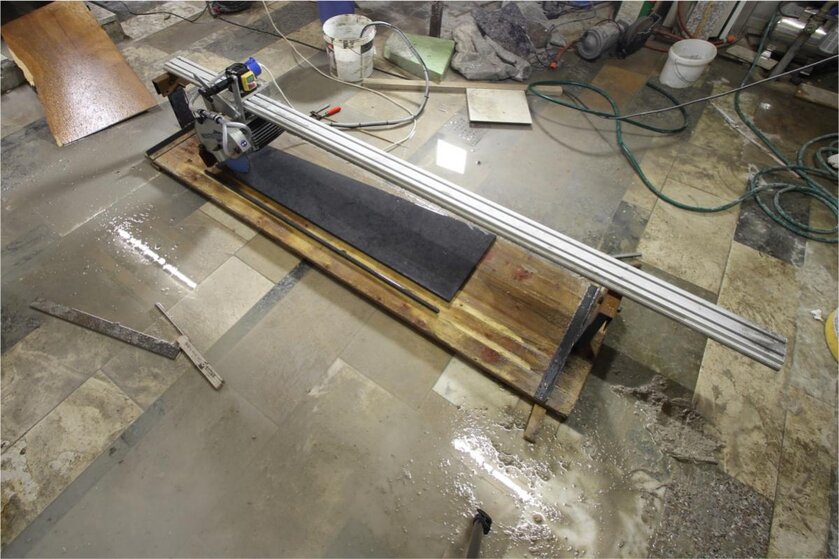

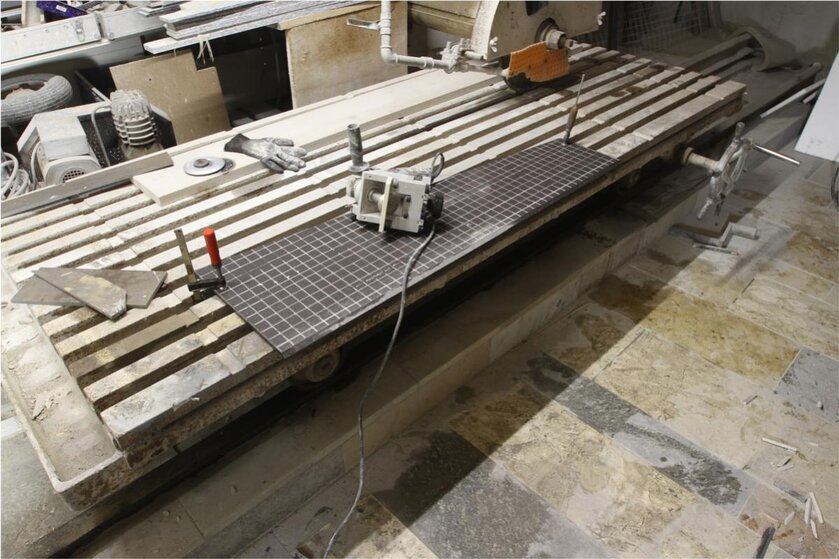

so last weekend i customized my mobile wet saw for long tiles ( 2.30m) in a mitre-able wet saw. i weld two adjustable supports. now i can mitre 2m tiles or natural stone.

so a little bit about the basic machine: it was my 100cm wet saw from englhard.

for a year i ordered a long railprofile to have a wet saw for difficult 120cm tiles and the 180cm tiles in future.

the machine looks very wild but it cuts very very exactly (i love it) and its very lightweight. i´m a one man service so this is very important for me.

let me say for me its not a problem to make exact mitre´s on granit or marble. and for the normal tiling job it is no problem with this or other machines to cut a 45 or 46 degree edge.

but if you want a perfect 45,00 ° edge on hard porcelain gres it is not easy with wet saws because every diamond blade drifts away. even on the bigger bridge saws.

i talked about this problem with italmont and the say yes its a problem.

with a brand new and perfekt tuned diamond blade it workes but then after time and a few cuts its over.

with a new 45° cutter in the rondomax its ok but then one side outwears faster.

so the result is okay and you can sand it a little bit and use it for tiling. but the result is no 100% perfect 45° edge. i mean 45,0 and no 44 or 46.

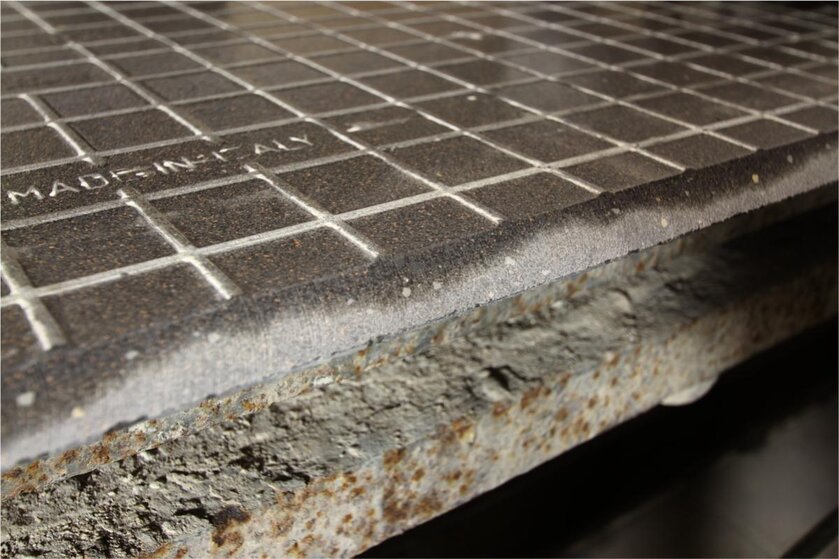

so my idea was when i saw the easy bevel mechanism that i use it on the backside of the tile to make mitres. i ordered it from italmont. the advantage of this tool is that the diamond tool lies in horizontal straight position to the material and is used completle on full surface.

the disadvantage of the esay bevel is the cost for the diamond tool. so i convert a customized cheap one on top and in future i don´t need the orginal ones from italmont. its also vacuum braced (K50) diamond and i can mitre more thick materials with it instead of the orginal which is restricted to 10mm bevel. cool!

the profiled backside of the tile is not ideal for the small weels but its not so hard to balance it. i use always vario grinders. i ordered a save shifter and a side watercooling to increase life time of the tool in future. and a 50 diameter diamond grinder for wet use. i write more about it next time.

View attachment 48135

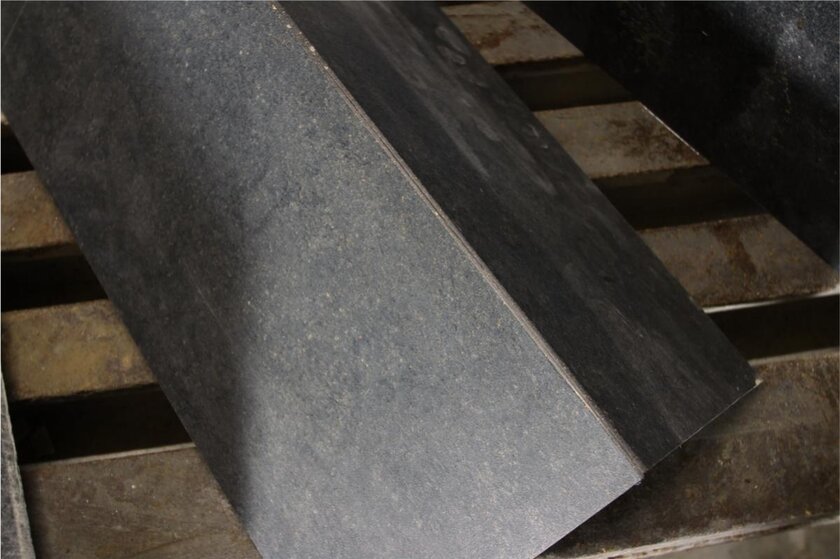

the second plate is the customized one. the first plate is the orginal diamond tool.

so i went zero to the edge. not leave one or half mm i wanted to go as sharp as possilbe. the tile is a atlas concorde 10mm 120x60 porcelain gres. as you see very crisp.

fits perfect in 90°

left one is a star galaxy granite. i cut it 46° with my wet saw and didn´t use the easy bevel. its no needed on natural stone.

middle one is the finished glued porcelain tile. i glued it with akemi akepox 5030 in black. i talked to akemi and its ok for tiles. next day i sanded the bevel.

a close up to the corner. its not perfect but for the first try i think its enough.

i showed the edge two of my customers and no i have to face a big vanity with tiles and this edge and next week i do all the mitred corners on building site in a toilet room. i´m a little bit afraid of it but i think its possible.

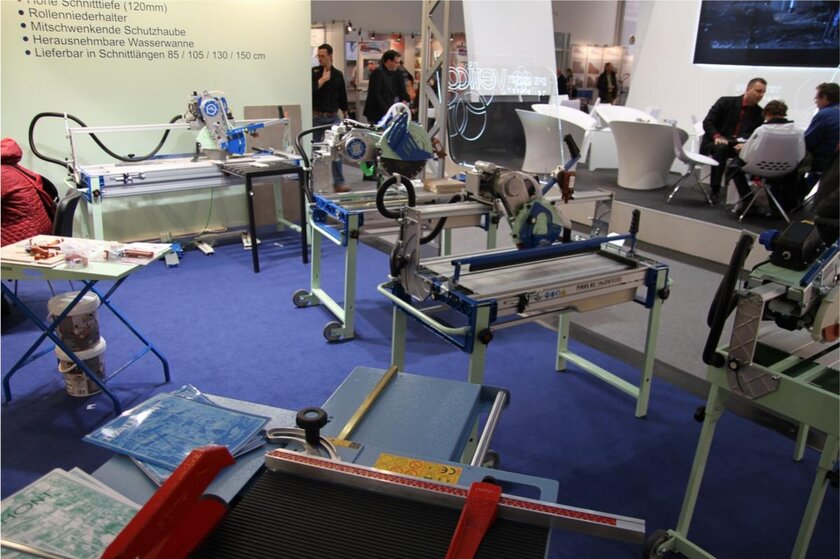

so monay its BAU fairy in munich. i want to buy a new wet saw. i have a little connection to kaufmann tools in austria and i will speak to the technican. i have the idea of a 3m mobile lightweight wet saw wich can make perfect mitres in crisp porcelain gres without using external tools. oh no, i spend all my money in tools!!!!!

in my winter holidays i thinked a lot about tony.

i do mitres in most of my jobs.

i have two wet saws in diffrent lengths and weights and i use the light one almost every day because i can drag it out of my car in seconds and use it outdoor or indoor in my self built wet box.

but last year i had two jobs where i can´t use my wet saws. 5th floor and no place for it or the tiles were to long and heavy to handle on the mobile saws.

so last weekend i customized my mobile wet saw for long tiles ( 2.30m) in a mitre-able wet saw. i weld two adjustable supports. now i can mitre 2m tiles or natural stone.

so a little bit about the basic machine: it was my 100cm wet saw from englhard.

for a year i ordered a long railprofile to have a wet saw for difficult 120cm tiles and the 180cm tiles in future.

the machine looks very wild but it cuts very very exactly (i love it) and its very lightweight. i´m a one man service so this is very important for me.

let me say for me its not a problem to make exact mitre´s on granit or marble. and for the normal tiling job it is no problem with this or other machines to cut a 45 or 46 degree edge.

but if you want a perfect 45,00 ° edge on hard porcelain gres it is not easy with wet saws because every diamond blade drifts away. even on the bigger bridge saws.

i talked about this problem with italmont and the say yes its a problem.

with a brand new and perfekt tuned diamond blade it workes but then after time and a few cuts its over.

with a new 45° cutter in the rondomax its ok but then one side outwears faster.

so the result is okay and you can sand it a little bit and use it for tiling. but the result is no 100% perfect 45° edge. i mean 45,0 and no 44 or 46.

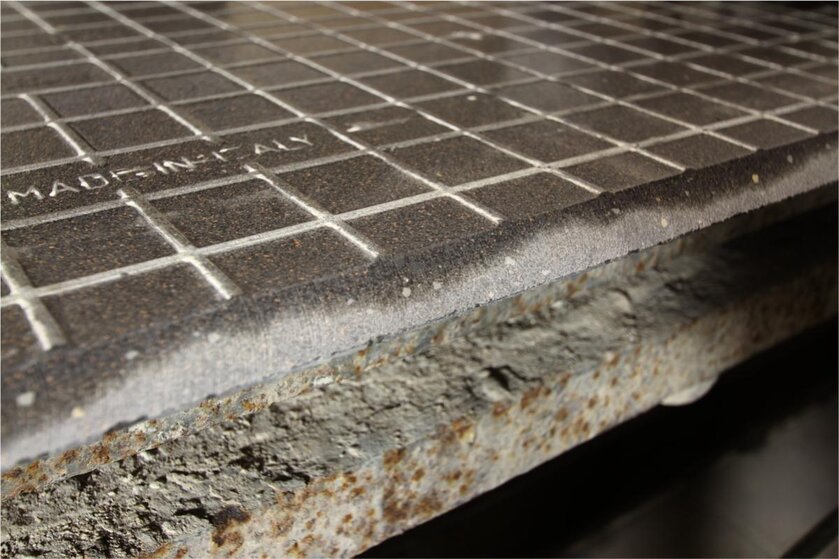

so my idea was when i saw the easy bevel mechanism that i use it on the backside of the tile to make mitres. i ordered it from italmont. the advantage of this tool is that the diamond tool lies in horizontal straight position to the material and is used completle on full surface.

the disadvantage of the esay bevel is the cost for the diamond tool. so i convert a customized cheap one on top and in future i don´t need the orginal ones from italmont. its also vacuum braced (K50) diamond and i can mitre more thick materials with it instead of the orginal which is restricted to 10mm bevel. cool!

the profiled backside of the tile is not ideal for the small weels but its not so hard to balance it. i use always vario grinders. i ordered a save shifter and a side watercooling to increase life time of the tool in future. and a 50 diameter diamond grinder for wet use. i write more about it next time.

View attachment 48135

the second plate is the customized one. the first plate is the orginal diamond tool.

so i went zero to the edge. not leave one or half mm i wanted to go as sharp as possilbe. the tile is a atlas concorde 10mm 120x60 porcelain gres. as you see very crisp.

fits perfect in 90°

left one is a star galaxy granite. i cut it 46° with my wet saw and didn´t use the easy bevel. its no needed on natural stone.

middle one is the finished glued porcelain tile. i glued it with akemi akepox 5030 in black. i talked to akemi and its ok for tiles. next day i sanded the bevel.

a close up to the corner. its not perfect but for the first try i think its enough.

i showed the edge two of my customers and no i have to face a big vanity with tiles and this edge and next week i do all the mitred corners on building site in a toilet room. i´m a little bit afraid of it but i think its possible.

so monay its BAU fairy in munich. i want to buy a new wet saw. i have a little connection to kaufmann tools in austria and i will speak to the technican. i have the idea of a 3m mobile lightweight wet saw wich can make perfect mitres in crisp porcelain gres without using external tools. oh no, i spend all my money in tools!!!!!