Along with this....very useful info...

Where Should Movement Joints Be Fitted?

The theory is to create "tile fields" large enough to absorb differential movement between the substrate and the ceramic or stone covering -- movement joints must be installed in certain areas and positions to prevent tiles or grout from cracking...and in some cases prevent the tiles from tenting and becoming debonded from the substrate. But the exact positioning of movement joints is vital to them successfully protecting the installation. If they're installed in the wrong place they won't work.

Industry guidelines suggest that the maximum tile field should be no more than ten metres in each direction - but in practice, depending on the individual applications, it tends to be between five and eight metres.

British Standards (BSI) 5385 covers the requirements and methods for movement joint applications. Part 3: 1989-Section 3 - 19.1.1 states that the building designer should assess the magnitude of any stresses and decide where movement joints should be located, having regard to all relevant factors, including the type of flooring, bed and substrate.

While the floor areas to be tiled come in all shapes and sizes there is a general formula for working out where movement joints should be placed.

A circle provides the best configuration for movement joints, because the forces from the centre are equal in each direction. However, in practice, because hardly any floors are circular, it is best to look at square floors and rectangular floors. In a square configuration the ideal field size is where the ratio of the shortest to the longest distance from the centre of the force is approximately 1:1.5 (see figure 1) -- for example 5 x 7.5 metres. Generally, the tile "field" should be kept as square as possible, and where underfloor heating is present, the tile field should not exceed 40 square-metres.

However, most floors tend to be rectangular, rather than square, though. And rectangular shapes tend not to be the best configuration, as the ratio of the shortest to the longest distances exceeds 1:1.5. In the example shown in figure 2 the crack risk is at the centre of the area. If no movement joint has been installed, cracking of the tiled surface is highly likely. In large floors it is advisable to incorporate movement joints forming bays at no more than 30-metre intervals. Each bay is then sub-divided into smaller bays by stress relieving joints not greater than ten metres apart.

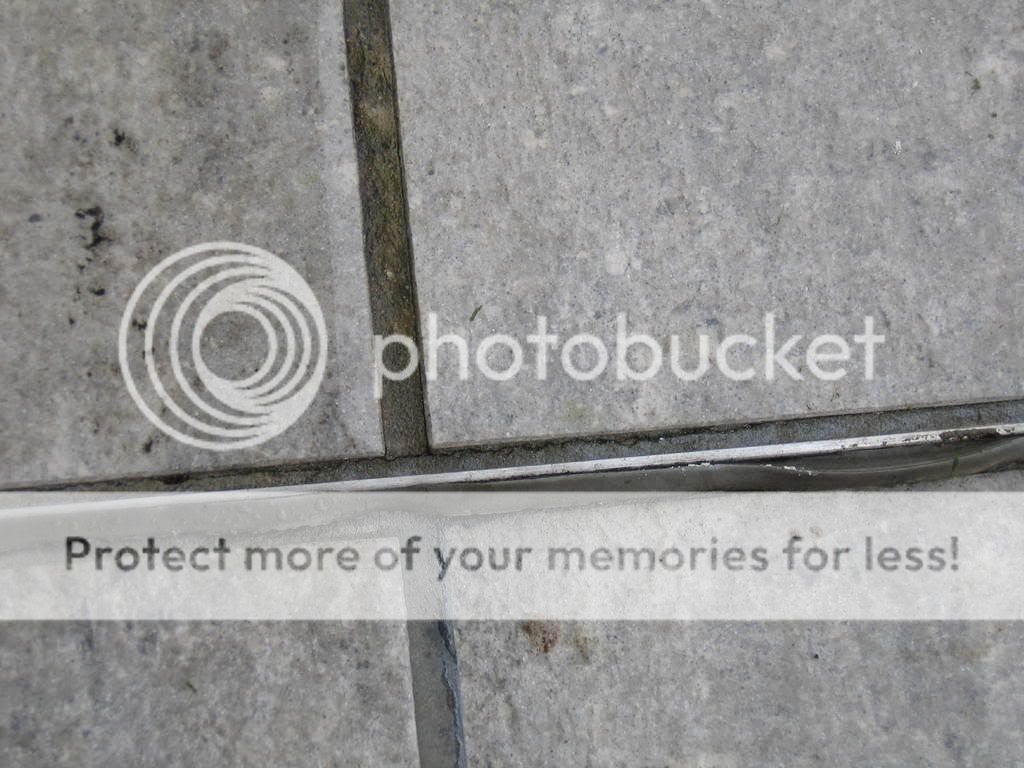

On suspended floors, stress-relieving joints should be inserted where flexing is likely to occur...for instance, over supporting walls or beams. And, as always, joints must be situated directly over any joints in the substrate,

and at any changes in the substrate, such as timber to screed.

For areas less than two metres wide perimeter joints are not normally required, unless conditions generate stresses which are likely to become extreme, for example temperature changes.