T

tim441

I will be grateful for suggestions and advice on best grout and 'how to' tips for scenario below:

1. Anhydrite liquid screed over wet UFH

2. 22mm indian sandstone installed with Granfix CSR flexi adhesive. Joints approx 10-15mm

3. sandstone is grey and used externally on patio as well with mortar joints tooled with rounded joiner tool

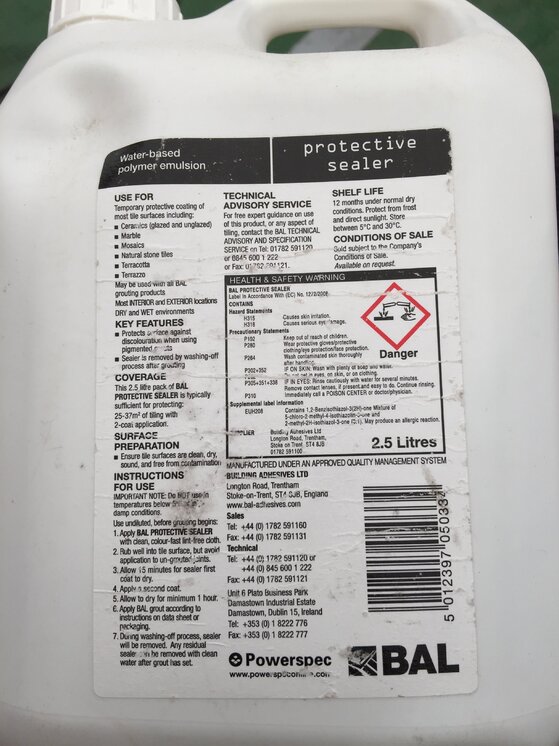

Plan is to seal with Geofix stone protector

Questions: Grout options?

1. Was planning to use Granfix Maxigrout - wide joint/flexible. But bit concerned whether its going to be very painful to use due to riven surface and cleaning it up etc. Any tips or suggestions how to most efficiently use a grout of this type? Want to minimise work but get good finish! Presumably using traditional sponges etc will just rip sponges and be a nightmare to clean grout from sandstone

i) best to use a grout bag?

ii) finish with rounded jointer tool?

2. Is it possible to use sand/cement mixed with flexible additive? if so what mix and type additive do you suggest?

3. any other tips and suggestions welcomed!

thanks!

1. Anhydrite liquid screed over wet UFH

2. 22mm indian sandstone installed with Granfix CSR flexi adhesive. Joints approx 10-15mm

3. sandstone is grey and used externally on patio as well with mortar joints tooled with rounded joiner tool

Plan is to seal with Geofix stone protector

Questions: Grout options?

1. Was planning to use Granfix Maxigrout - wide joint/flexible. But bit concerned whether its going to be very painful to use due to riven surface and cleaning it up etc. Any tips or suggestions how to most efficiently use a grout of this type? Want to minimise work but get good finish! Presumably using traditional sponges etc will just rip sponges and be a nightmare to clean grout from sandstone

i) best to use a grout bag?

ii) finish with rounded jointer tool?

2. Is it possible to use sand/cement mixed with flexible additive? if so what mix and type additive do you suggest?

3. any other tips and suggestions welcomed!

thanks!