P

Peter

Tried out the ATS turbo 115mm blade today as a replacement for my very average Addax turbo blade.

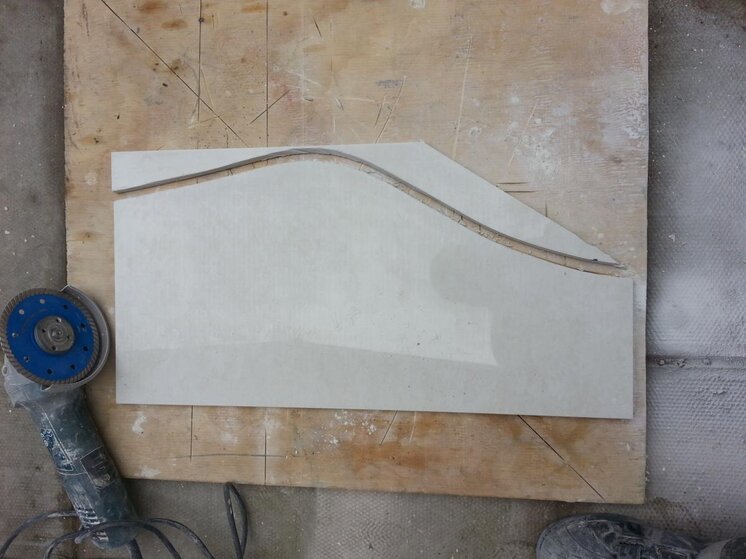

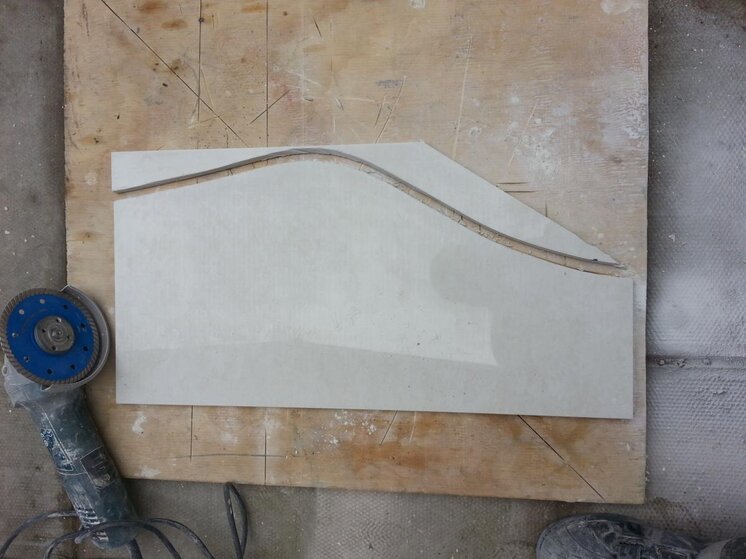

Had an S shape tray to cut round so that was it's first job, on 600x300 polished porcelain. It cut better than I expected it to and although there was some chipping, it wasn't any worse than some blades for twice the money. Interestingly it was able to cut the fine sliver off the tile in one peice that my other blade would have broken. Used it a few more times through the day and not sure if it was just me or the type of cut, but chipping didn't seem as bad by the end of the day. Time will tell but first impressions for £14 it's not a bad blade at all.

Had an S shape tray to cut round so that was it's first job, on 600x300 polished porcelain. It cut better than I expected it to and although there was some chipping, it wasn't any worse than some blades for twice the money. Interestingly it was able to cut the fine sliver off the tile in one peice that my other blade would have broken. Used it a few more times through the day and not sure if it was just me or the type of cut, but chipping didn't seem as bad by the end of the day. Time will tell but first impressions for £14 it's not a bad blade at all.