I can't be the only to start a job and get stung with the amount of work in it.

Typical bathroom renewal. Typically 5 days start to finish.

This one has been anything but! Normally takes a day, day and a half max stripping all the old tiles off. Marble on the walls, so I knew this would take a bit longer. Partition wall to come down aswell. Well shortly after stripping some tiles of I quickly realise that the tiles are stuck on the wall with latex based adhesive. Bad enough in its own right. Next comes the realisation that the walls are 18mm marine ply!! Never in my life have a seen this in a bathroom.

2 and a half days to strip it down with 3 men on site. Plumber comes up for his first fixings. Shower pipe and radiator pipes are hooked up to the mains. Which so happens to be a communal boiler system located in the basement. We had to turn the heating off for the entire building (it is a art deco block of flats) and then drain the whole system. This took nearly 4 hours to do alone!

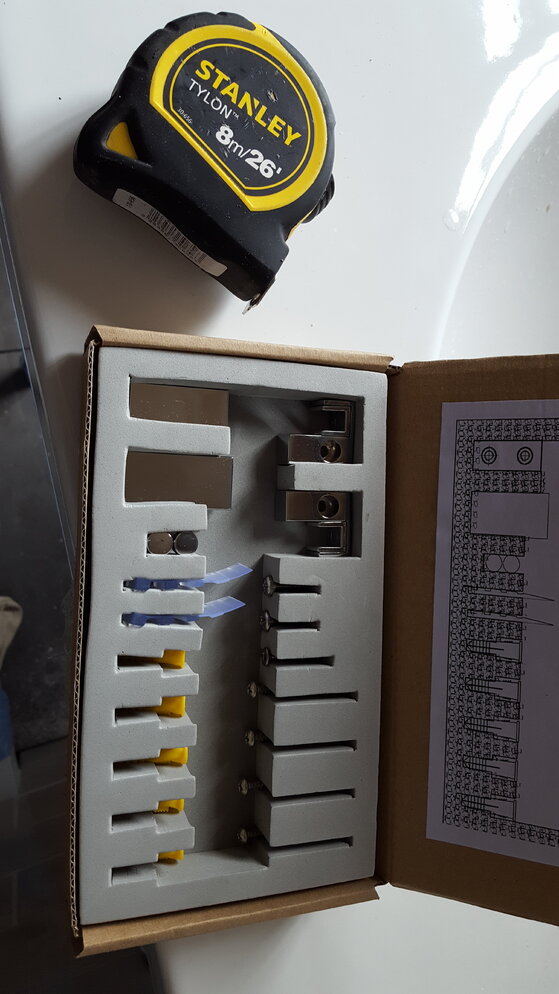

So 8 days later the spark was in today, then the plasterer. Wee bit of tiling to finish and lastly plumber is back for his final fixings.

Anyone else had a nightmare experience from what was ment to be a simple job?

Typical bathroom renewal. Typically 5 days start to finish.

This one has been anything but! Normally takes a day, day and a half max stripping all the old tiles off. Marble on the walls, so I knew this would take a bit longer. Partition wall to come down aswell. Well shortly after stripping some tiles of I quickly realise that the tiles are stuck on the wall with latex based adhesive. Bad enough in its own right. Next comes the realisation that the walls are 18mm marine ply!! Never in my life have a seen this in a bathroom.

2 and a half days to strip it down with 3 men on site. Plumber comes up for his first fixings. Shower pipe and radiator pipes are hooked up to the mains. Which so happens to be a communal boiler system located in the basement. We had to turn the heating off for the entire building (it is a art deco block of flats) and then drain the whole system. This took nearly 4 hours to do alone!

So 8 days later the spark was in today, then the plasterer. Wee bit of tiling to finish and lastly plumber is back for his final fixings.

Anyone else had a nightmare experience from what was ment to be a simple job?