Forgive me for I am noob...

I have a 9m x 9m floor area that is one space, but half is a new build extension and half is 1920's old house

Situation:

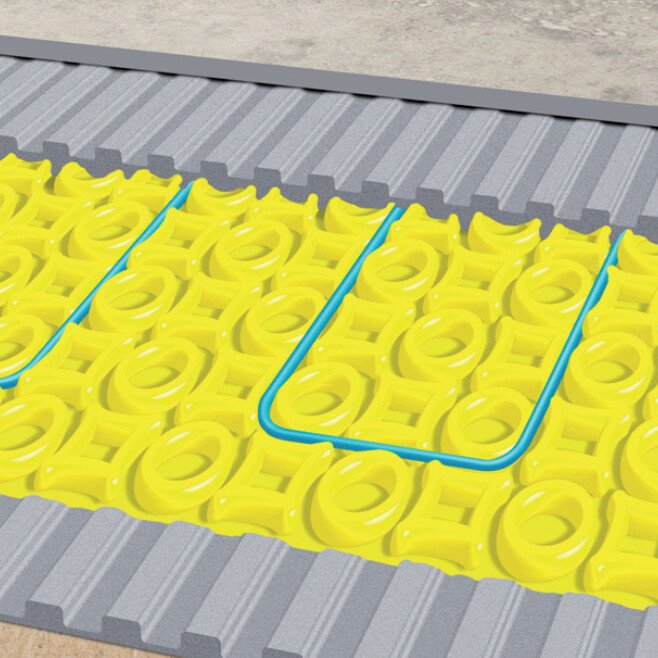

The new build half has a Anhydrite screed floor with UFH.

The old half is concrete floor WITHOUT UFH.

The tiles are 1200mm x 600mm porcelain.

The surfaces are not quite level (old house floor is 20mm lower) but finished surface needs to be continuous level floor

Actions so far:

-Screed was laid last year

-I have sanded back the laitance on the Anhydrite screed (not that there seamed to be much to sand??)

-UFH has been running for 3 days with no cracking.

Current thinking/plans:

-SBR mixed 1:1 with 2 coats on the floor at 90 degrees to each other on new anhydrite floor.

-Anyhyfix tile adhesive on the Anhydrite floor (I would like a slow setting alternative if there is one?)

-Mapai Keraquick/latex plus on old floor (is there a cheaper slow setting alternative that is good? Do I need the latex plus?)

-'Backbutter' the tiles

-3mm tile spacers

-Foam and silicone expansion joints every 3 tiles or so?

-Foam and silicone expansion joint all along where the old concrete floor meets the new anhydrite screed.

-Not sure how to best raise the old house floor 20mm. I was thinking of using a decoupling mat on the old house, or perhaps use self leveling compound and put a electric UFH mat in there too?

Any advice appreciated. I have done a little tiling before, but this is way past that!

Thanks.

I have a 9m x 9m floor area that is one space, but half is a new build extension and half is 1920's old house

Situation:

The new build half has a Anhydrite screed floor with UFH.

The old half is concrete floor WITHOUT UFH.

The tiles are 1200mm x 600mm porcelain.

The surfaces are not quite level (old house floor is 20mm lower) but finished surface needs to be continuous level floor

Actions so far:

-Screed was laid last year

-I have sanded back the laitance on the Anhydrite screed (not that there seamed to be much to sand??)

-UFH has been running for 3 days with no cracking.

Current thinking/plans:

-SBR mixed 1:1 with 2 coats on the floor at 90 degrees to each other on new anhydrite floor.

-Anyhyfix tile adhesive on the Anhydrite floor (I would like a slow setting alternative if there is one?)

-Mapai Keraquick/latex plus on old floor (is there a cheaper slow setting alternative that is good? Do I need the latex plus?)

-'Backbutter' the tiles

-3mm tile spacers

-Foam and silicone expansion joints every 3 tiles or so?

-Foam and silicone expansion joint all along where the old concrete floor meets the new anhydrite screed.

-Not sure how to best raise the old house floor 20mm. I was thinking of using a decoupling mat on the old house, or perhaps use self leveling compound and put a electric UFH mat in there too?

Any advice appreciated. I have done a little tiling before, but this is way past that!

Thanks.

Last edited: