Hi all,

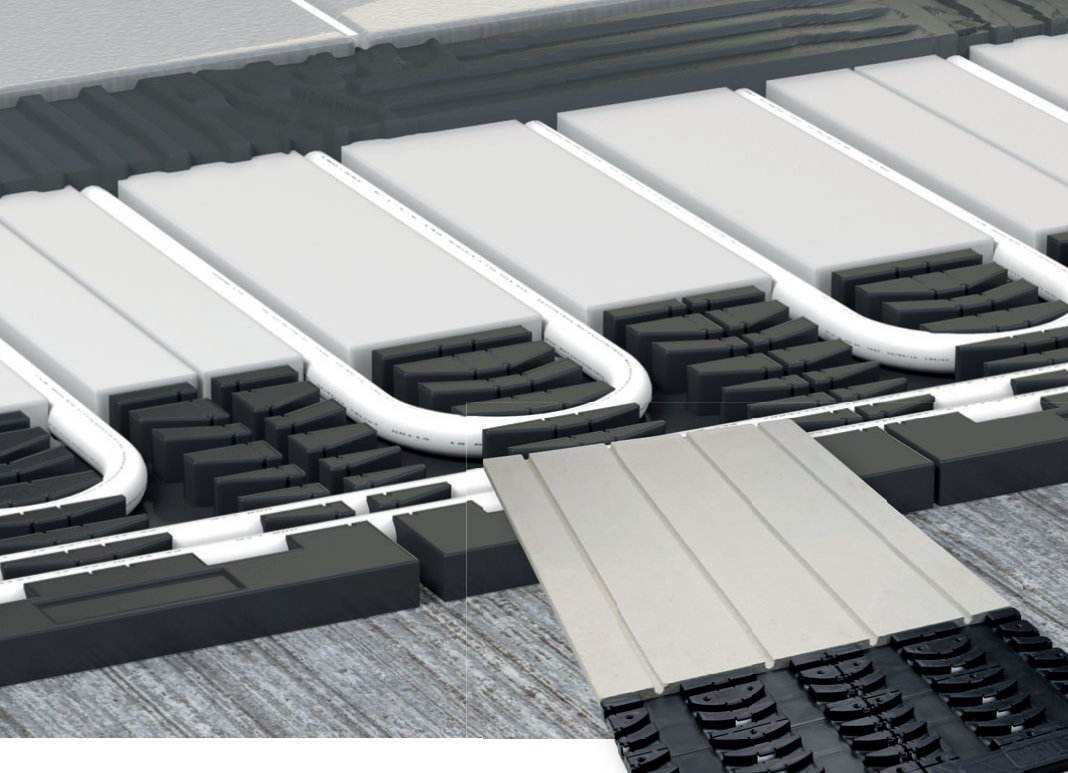

I've put water underfloor heating down in our bathroom using "ProWarm Warm panel" which are panels with premade tracks for the pipes in wet rooms. The panels are glued together but not glued down (consistent with manufacturers instruction) and with plastic end panels which enables the pipe to turn back - these are screwed down to the plywood. I found it strange that the warm panels are not glued/fixed down, any comments would be appreciated). Under the panels I have 18mm PLY on top of wooden joists with kingspan in between joists.

Apparently the UFH panels can be tiled onto directly - however the company that sells them recommends a 6mm ply to be used between boards and tiles - this sounds strange to me but I am a bit scared tiling directly as well as the pipes are exposed so could be damaged by mistake.

To summarise:

Many thanks,

Jon

I've put water underfloor heating down in our bathroom using "ProWarm Warm panel" which are panels with premade tracks for the pipes in wet rooms. The panels are glued together but not glued down (consistent with manufacturers instruction) and with plastic end panels which enables the pipe to turn back - these are screwed down to the plywood. I found it strange that the warm panels are not glued/fixed down, any comments would be appreciated). Under the panels I have 18mm PLY on top of wooden joists with kingspan in between joists.

Apparently the UFH panels can be tiled onto directly - however the company that sells them recommends a 6mm ply to be used between boards and tiles - this sounds strange to me but I am a bit scared tiling directly as well as the pipes are exposed so could be damaged by mistake.

To summarise:

- Is it strange that the panels are 'floating' on the plywood and, if so, how would you fix them?

- Would you tile directly on top of the UFH boards? If not, what would you put on top and how would you fix it?

Many thanks,

Jon